Specification

| MOQ | 500pcs. More quantity, more favorable price. |

|---|---|

| Material | PET/VMPET/PE or customized. |

| Size |

60Wx175H mm,Accept customized size

|

|

Production time

|

12-15 days

|

|

Place of Origin

|

Guangdong, China

|

|

Surface Handling

|

Gravure printing and Surface Handling |

|

Material Structure

|

PET/VMPET/PE/customized

|

|

Printing

|

1colors,Up to 10 colors

|

|

Supply Ability

|

100000 Piece/Pieces per Day

|

What is the child-resistant packaging requirements?

Child-resistant packaging (CRP) is a type of packaging designed to prevent children from opening or accessing potentially harmful products such as medicines, pesticides, or household chemicals. CRP must meet certain performance requirements and test methods regulated by the U.S. Consumer Product Safety Commission (CPSC) under the Poison Prevention Packaging Act (PPPA).

Some examples of CRP are safety caps, blister packs, or unit dose packaging. CRP must also be easy for adults to use properly, especially for seniors who may have difficulty with some types of packaging. CRP is required for certain over-the-counter (OTC) products such as acetaminophen, aspirin, diphenhydramine, or ibuprofen.

At Mylarpac, we understand the importance of safety packaging and the impact it has on preventing illnesses and injuries. We offer a wide selection of child-resistant packaging solutions to meet different needs – from simple one-piece closures to more complex designs with multiple components. All CRP materials used by us comply with CPSC standards for toxicity and strength, ensuring your products remain safe and secure. Whether you’re looking for custom printed packages or simply need an off-the-shelf solution, our team is here to help. Contact us today to learn more about how our child-resistant packaging can ensure safety and peace of mind!

Child-resistant packaging options:

Why choose child-resistant bags?

As parents, we always want to ensure the safety of our little ones. That’s why the child-resistant packaging requirements are essential for products that may pose a hazardous threat, such as medication, cleaning supplies, or chemicals. Child-resistant packaging is designed to be difficult for children to open, but easy for adults to access. Child-resistant bags have become increasingly popular, especially for cannabis products, allowing dispensaries to comply with safety regulations. These child proof bags have locking mechanisms or seals that need to be opened in a specific way, proving effective in preventing accidental ingestion or exposure. With child-resistant packaging requirements, we can rest easy knowing that our curious children won’t be able to access potentially dangerous items. At Mylarpac, we specialize in child-resistant packaging for all types of products. Our team offers custom printing and design services to tailor packaging solutions that meet the needs of your product and brand. Contact us today for more information about our child-resistant packaging solutions.

List the types of child proof bags

Child proof bags are designed to prevent children from accessing harmful substances or objects. Here are some types of child proof bags mentioned in the search results:

- Aerosol bags: These bags are often used to package medicines and medical supplies. They create a vacuum seal on the inside of the bag to prevent accidental ingestion and misuse by children. The vacuum seal helps to draw out the air inside the bag to preserve the medicine.

- Anti-choking bags: These bags are designed to prevent children from choking by putting the bag in their mouth or nose. They are vacuum-sealed like vaping bags, but have a small hole that allows children to breathe air without putting the bag in their mouth or nose.

- Flexible packaging bags: These bags are commonly used to package liquids, powders and small particulate substances such as pharmaceuticals and hazardous chemicals. They have a double protective function to prevent children from eating or misusing the contents. The bags can be sealed to prevent accidental ingestion and are made from crush resistant materials to withstand extrusion and stretching.

- Tamper evident bags: These child-resistant plastic bags are designed to be relatively difficult for children to open. They use special closure technology to ensure that children cannot easily access the contents. These bags are made with materials and construction that provide increased safety and protection.

In addition to the above types of pouches, there are other types of child-resistant packaging, such as

- Child-resistant pill bottles with push and twist lids

- Child-resistant tins with push and twist or tamper evident lids

- Child-resistant jars with push and twist lids

- Child-resistant bags with reclosable or zip fasteners

It’s important to note that child-resistant packaging must meet specific regulations and testing requirements. The US Consumer Product Safety Commission (CPSC) regulates child-resistant packaging under the Poison Prevention Packaging Act (PPPA). The packaging must make it significantly more difficult for a child under the age of five to open or to obtain a toxic or harmful amount of the substance within a reasonable time. At the same time, it should not be difficult for a normal adult to use properly.

Child-resistant packaging is tested by having children between the ages of three and five try to open the packaging. The packaging must meet certain criteria, such as not being opened by at least 85% of children before and after a demonstration, and being accessible to 90% of older adults.

The most popular material for child proof bags

At Mylarpac, we often use mylar material to make child proof bags, and it is also the most popular material for child-resistant bags on the market. And what are the benefits of mylar material in child safety bags?

- Safety and compliance: Child proof mylar bags are designed to meet state and federal regulations for child-resistant packaging. They provide a tamper-evident seal to ensure the integrity and safety of the contents.

- Durability and resilience: Mylar bags are known for their durability and resilience, making them a preferred choice for packaging cannabis products. They can withstand handling and transportation without the risk of breakage or leakage.

- High barrier protection: Child proof mylar bags are made with a high barrier material, such as foil or quad-layer plastic, to provide protection against moisture, oxygen, and light. This helps to preserve the quality and freshness of the contents inside the bag.

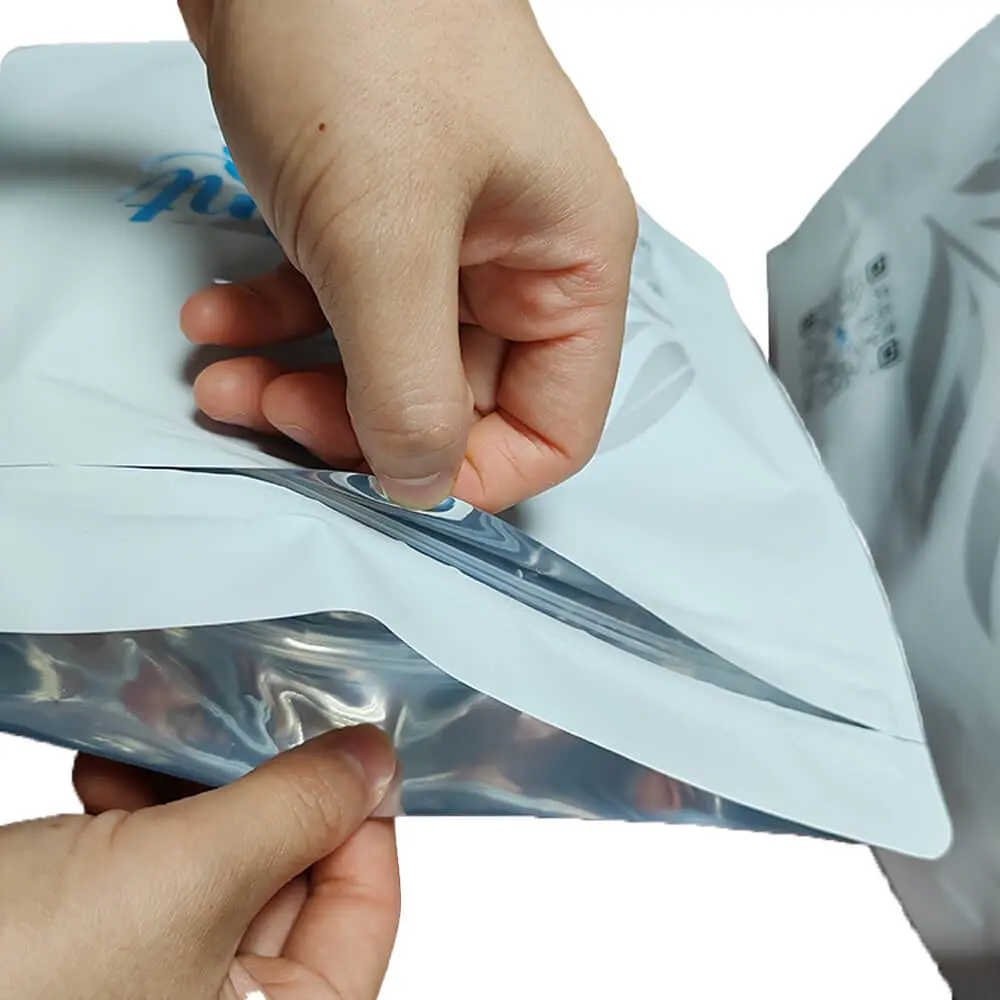

- Child-resistant closures: Child proof mylar bags often feature special closure mechanisms that require coordination and dexterity to open, making them difficult for children to open. Examples of child-resistant closures include Pinch N Pull or Pinch N Slide closures.

- Odor control: Child-resistant mylar bags have properties that help to conceal scents, making them suitable for packaging products with strong odors.

- Cost-effective and versatile: Child proof mylar bags are cost-effective compared to other packaging options like glass jars. They are lightweight, easy to handle, and convenient for storage and transportation.

- Customization options: Child proof mylar bags can be customized with various designs and sizes to suit different product requirements.